Laser technology has revolutionized the way we mark and engrave items. With laser etching, you can create precise markings, logos, designs, and text on almost any surface. It is a fast, accurate, and cost-effective way to leave a permanent impression on materials, making it perfect for use in medical, automotive, electronics, aerospace component manufacturing, and other industries.

What is Laser Etching?

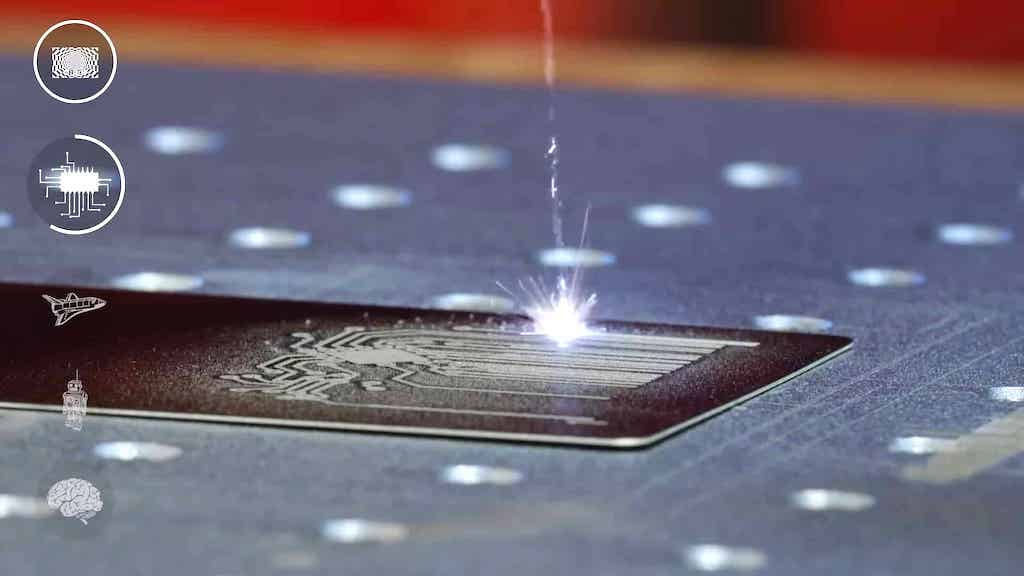

Laser etching is a process used to create permanent markings on a variety of materials. It involves using a high-energy laser beam, which heats specific regions of the surface to change its color or texture, leaving a permanent, precise, and accurate mark. It can be used to mark almost any metal or non-metal surface, including plastics, acrylics, glass, leather, and wood.

How Does Laser Etching Work?

In laser etching, the laser beam is focused onto the material's surface, which absorbs the beam's energy, creating heat. As the heat builds up, a localized color change occurs on the material, creating a permanent mark. The laser beam's intensity can be adjusted to create different surface effects, such as deep engraving or shallow etching.

Why Use Laser Etching?

Laser etching offers many advantages over other marking methods, such as chemical etching or stamping. It is a non-contact method, meaning that no physical contact is made between the marking tool and the surface, making it perfect for delicate materials such as electronic components. It is also a highly precise method, allowing you to create highly detailed markings and logos, which cannot be achieved using other methods. Additionally, the process is fast, reducing production times and costs, and it can be used on a variety of materials, making it versatile and cost-effective.

Applications of Laser Etching

Laser etching has multiple applications across different industries, including:

Medical: Medical devices require precise marking for identification and traceability purposes. Laser etching can mark almost any type of material used in the production of medical devices.

Automotive: Automotive components must be marked to ensure traceability throughout the production process. Laser etching provides quick, precise, and permanent markings on metal and plastic parts.

Electronics: Electronic components require marking for identification, tracking, and traceability purposes. Laser etching can create clear, permanent markings on circuit boards, switches, and other electronic components.

Aerospace: Aerospace manufacturing requires highly accurate markings for identification and traceability. Laser etching provides permanent markings on a range of materials used in the aerospace industry.

Conclusion

With laser etching, you can create permanent, high-quality markings, logos, designs, and text on a variety of surfaces. It is a fast, accurate, and cost-effective process, making it the perfect choice in multiple industries, such as medical, automotive, electronics, and aerospace. Contact Sistem Laser Etching today to experience the future of permanent markings!