In recent years, the textile industry has witnessed significant technological advancements that have led to the development of high-end cutting machines that are more efficient and effective. One such cutting technology is the high-power laser cleaning system, which has been gaining popularity in the textile industry due to its numerous benefits.

High-power laser cleaning is a process that involves removing contaminants, rust, and other unwanted substances from the surface of materials using an intense laser beam. This process is highly effective, requires minimal maintenance, and does not produce any harmful by-products.

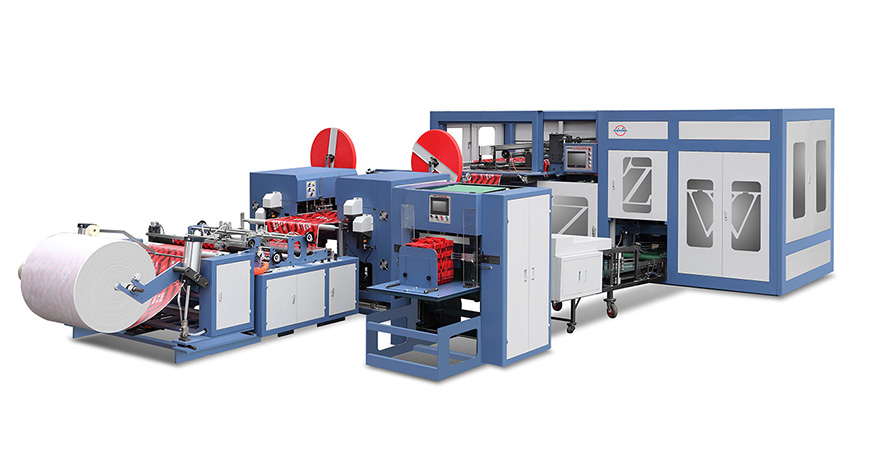

The use of high-power laser cleaning in woven-bag cutting machines has revolutionized the textile industry. The benefits of this technology are numerous and include:

Improved Precision and Accuracy

High-power laser cleaning technology allows for precise, accurate, and uniform cutting of woven bags. The laser beam is precise, and it follows the cutting path accurately, ensuring that the bags are cut in the right shape and size. This results in improved quality and consistency in the finished products.

Increased Efficiency and Productivity

The high-speed laser beam used in this cutting technology is significantly faster compared to traditional cutting methods. This means that more bags can be cut within a shorter period, leading to increased productivity and efficiency. Additionally, the machines do not require any downtime for routine maintenance, reducing the overall time spent on production.

Reduced Material Waste

Cutting machines that use high-power laser cleaning technology produce minimal material waste since the cutting beam is precise and follows the cutting path accurately. Therefore, there is minimal material wastage, which reduces the cost of production and enhances the efficiency of the manufacturing process.

Cost-effective

Although high-power laser cutting machines are initially more expensive compared to traditional cutting machines, they are more cost-effective in the long run. They have a longer lifespan and require minimal maintenance, reducing operating and maintenance costs. Additionally, they produce minimal material waste, which saves on production costs.

Environmentally friendly

High-power laser cutting machines do not produce any harmful by-products, making them environmentally friendly. They do not emit any pollutants into the atmosphere or release any chemicals that can harm the environment. This makes them a sustainable option for the textile industry.

In conclusion, the use of high-power laser cleaning technology in woven-bag cutting machines has transformed the textile industry. The benefits of this technology, including improved precision, accuracy, efficiency, and productivity, reduced material waste, and cost-effectiveness, have led to its widespread adoption. Moreover, it is environmentally friendly and sustainable, making it a preferred option in the textiles industry.