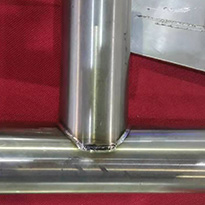

A variety of hand-held laser heads are available for various needs such as external welding, internal welding, right-angle welding, narrow-side welding, and large spot welding, etc. Electro-optical conversion rate-high laser light output per second is optional. Not only can do pulse welding, but also continuous welding at high frequencies.

A variety of hand-held laser heads are available for various needs such as external welding, internal welding, right-angle welding, narrow-side welding, and large spot welding, etc. Electro-optical conversion rate-high laser light output per second is optional. Not only can do pulse welding, but also continuous welding at high frequencies. Welding capacity expands from small parts to large heavy-duty objects, advantageous in welding workpieces of different size. Romove distance laser welding job ability can be adjusted with multi-length options of the fiber cable. Optical transmission fiber is optional on demand 5/10/20 meters, up to the range of free-to adjust.

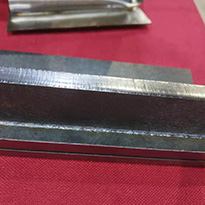

Welding capacity expands from small parts to large heavy-duty objects, advantageous in welding workpieces of different size. Romove distance laser welding job ability can be adjusted with multi-length options of the fiber cable. Optical transmission fiber is optional on demand 5/10/20 meters, up to the range of free-to adjust.  Kitchenware industry application- laser welding of 3-4mm thickness of stainless steel pots and pans. The 2000W power hand-held laser welding machine for kitchen utensils saves about 80%~90% of electric energy. Compared with arc welding, the processing cost can be reduced by about 30%. The amount of deformation after welding is very small, and a very beautiful welding surface can be obtained, and there is little subsequent processing of welding.

Kitchenware industry application- laser welding of 3-4mm thickness of stainless steel pots and pans. The 2000W power hand-held laser welding machine for kitchen utensils saves about 80%~90% of electric energy. Compared with arc welding, the processing cost can be reduced by about 30%. The amount of deformation after welding is very small, and a very beautiful welding surface can be obtained, and there is little subsequent processing of welding. By virtue of the camera and the welding spot identification system of the handheld laser welding machine, the confitions of insufficient welding and omitted welding can be avoided effectively and therefore, the welding quality is guaranteed.

By virtue of the camera and the welding spot identification system of the handheld laser welding machine, the confitions of insufficient welding and omitted welding can be avoided effectively and therefore, the welding quality is guaranteed.  A variety of hand-held laser heads are available for various needs such as external welding, internal welding, right-angle welding, narrow-side welding, and large spot welding, etc. Together with higher-speed and lower-cost processing, the high uptime and availability of the laser welding system enabled by the zero-maintenance fiber mark for the lowest cost per part welding, and the fastest return on investment.

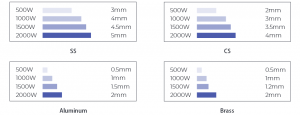

A variety of hand-held laser heads are available for various needs such as external welding, internal welding, right-angle welding, narrow-side welding, and large spot welding, etc. Together with higher-speed and lower-cost processing, the high uptime and availability of the laser welding system enabled by the zero-maintenance fiber mark for the lowest cost per part welding, and the fastest return on investment. All welding parameters have been tested and memorized in the operating software. The user only needs to call up the relevant parameters according to the welding materials and thickness, and then do the welding work directly. Only need 2-4 hours of training, even a fresh user also can operate the laser welding machine directly. It is no longer necessary to hire professional welders, which greatly save labor costs.

All welding parameters have been tested and memorized in the operating software. The user only needs to call up the relevant parameters according to the welding materials and thickness, and then do the welding work directly. Only need 2-4 hours of training, even a fresh user also can operate the laser welding machine directly. It is no longer necessary to hire professional welders, which greatly save labor costs. MORN LASER will provide professional and detailed operation manuals. The manual contains the various components of the machine, how to operate it, precautions, and maintenance proposal.

MORN LASER will provide professional and detailed operation manuals. The manual contains the various components of the machine, how to operate it, precautions, and maintenance proposal.